XCorr® Flat Patch is a carbon-epoxy composite repair system designed for sealing applications where localized repair is needed or full pipe wraps are impractical. XCorr® Flat Patch utilizes a premeasured 2-part novolac epoxy system combined with triaxial carbon fiber reinforcement fabrics and a technical felt to provide superior leak sealing capacity on flat surfaces. XCorr® Flat Patch is recommended for pressure applications up to 1,500 psi (105 kg/cm2) with a built in 4:1 safety margin. Return to service at pressure may be accomplished in ~5 hours for temperatures above 75°F.

Attributes

Below you can view more information about the XCorr® Flat Patch. If you have any questions, please call us today at 812-480-6656. For your convenience, click here to get a free quote from this site.

*Click on the Tabs to view more information.

Resin at 75°F (24°C)*

Ratio: 3:1

Pot Life: 35 minutes

Dry To Touch: 4 hours

Full Mechanical Strength: 24 hours

Full Chemical Resistance: 24 hours

*Pot life is greatly reduced with increased mixing volume and temperature. Cure time is significantly extended at lower temperature.

Composite

Repair Thickness: 0.15 in

Lap Shear Adhesion: 1,320 psi (ASTM D 3165)

Dry Adhesion: >3,000 psi (ASTM 4541)

Wet Adhesion: >3,000 psi, 5 days 158°F (70°C) water (ASTM 4541)

Sealing Pressure: 1,500 psi, based on patch repair of 0.125” od hole in flat steel plate

Compressive Strength: 10,000 psi (ASTM C109)

Shore D Hardness: 84 (ASTM D 785)

Temperature/Heat Resistance: From -20°F up to 350°F (-29°C to 177ºC) –continuous, dry. Consult chemical compatibility to gauge wet service perfomance.

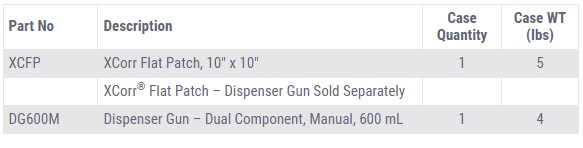

XCorr® Flat Patch Specifications

Packaging: Resin supplied in dual cartridge (parts A and B packaged separately) with pre-measured volumes sized. Kits provided with static mixers, spreaders and gloves. Two-part dispensing guns sold separately.

Sizes: Patch size- 10″ x 10″

Shelf Life: Part A: 12 months at 75°F (24°C). Part B: 12 months at 75°F (24°C)

Storage Temperature: 32 to 100°F (0 to 43°C), 0-100% relative humidity

Application Temperature: 50 to 150°F (10 to 65°C)

Surface Preparation: Surfaces must be cleaned of all oil and debris and dried. For metal surface, a bright metal finish is desired (SSPC-SP10 (immersion) or SSPC-SP6 (non-immersion)).

TecSolutions Consultants is a valued supplier to the utility locating and leak detection industry in the Southwest.

If you have any questions, please call TecSolutions Consultants today at 812-480-6656. For your convenience, click here to get a free quote from this site.

Thank you for your interest in TecSolutions Consultants. We look forward to serving you in the near future.

Products Available: Pipe & Cable Locators, Leak Detection, Ground Penetrating Radar GPR, Drain & Sewer Line Jetting, Inspection Cameras, Sonde, Conduit Rodders, and Utility Management Marking Equipment.

© TecSolutions Consultants All rights reserved.

Website Design by Brymels LLC.

Service Area Back to top